3 Double plane, Smoothing plane

(also: double roughing plane)

General

The double plane appears in the German-speaking area at the beginning of the 19th century. It is nothing more than a roughing plane with a double iron, which is why it was initially referred to as a double roughing plane. The dimensions and iron widths were almost identical. As already mentioned, it was clearly superior to this when working with difficult woods, fine, tear out free surfaces are much easier to achieve with this tool.

But it did not replace the roughing plane, but another plane: the hard or steep plane. This tool was used on hard and/or wild-masery woods, it was also used for finishing. The (single) iron was positioned steeper than at the roughing plane, perhaps around 60 degrees, it had similar dimensions to the toothing plane, so it was shorter than a roughing plane. The higher cutting angle enabled a finer chip removal on the one hand and on the other hand it also reduced tear-outs on the wood surface. The disadvantage was a noticeably higher resistance when planing. The double plane made finer work possible with lower effort, it became the standard tool within a few decades. Nevertheless, the hard plane apparently remained in production for quite a long time, with Weiss & Sohn it was last on offer in 1930.

In the case of moulding planes, where the use of a double iron is far too complicated or not possible at all, the principle of a steeper iron for the processing of hardwood has been maintained. In England there is also a terminology of his own, Charles Holtzapffel mentions in his book "Turning and Mechanical Manipulation" (London, 1846-1850) the terms "common pitch" (45 degrees), "york pitch" (50 degrees), "middle pitch" (55 degrees) and "half pitch" (60 degrees). In the German-speaking area, there are no corresponding terms for different cutting angles.

Double plane and Smoothing plane, Weiss & Sohn

Hard plane (Steep plane), Weiss & Sohn

Double plane vs. Smoothing plane

Today's distinction between double plane and smoothing plane seems to have established itself relatively late. In the documents of Weiss & Sohn, which are available to me, the term "Putzhobel (Smoothing plane)" first appeared in 1897. Under the catalogue number 3 a "double plane, short" is offered, under the number 3 1/2 a line further a "double plane short, smoothing plane for hardwood" (i.e. with steeply placed iron). Both unfortunately without illustration. Elsewhere, the term "putzhobel" appears earlier, for example in a price-courant of the company Balzer in Berlin from 1874.

In 1909 Weiss & Sohn had a more precise differentiation: there was the double plane in "normal length", a short smoothing plane (20 cm long) and a smoothing plane for hardwood (19 cm long, i.e. a hard plane with double iron). The double plane with lignum-vitae sole was also available as a long and short version. All these models also got their own catalog numbers.

But not only the length is a distinguishing feature between double plane and smoothing plane, but also the cutting angle. Over time, the smoothing plane received a higher cutting angle of around 50 degrees. Exactly when this change happened cannot be deduced from the catalogues and price lists. Nowhere is an indication of the cutting angle, neither with Weiss & Sohn nor with other manufacturers. The individual plane types (as well as the associated irons) were only precisely defined by the German Industrial Standard (DIN) after the Second World War. The last of these standards concerning joiner planes dates back to 1973 (they have now expired without replacement). It defines the plane types as follows:

The double iron

A double iron consists of 2 parts: the cutting iron and a second iron, which is placed in reverse, the cap iron (also called chip breaker).

The task of the cap iron is to bend the chip lifted from the cutting iron immediately after the cut. This bending causes a relatively strong tension of the wood fibers, whereby the cutting iron can cut the fibers much easier and cleaner. (The same effect can be observed if you want to cut an ordinary thin wooden stick with a knife: if you bend the stick a little, the wood fibres can be cut more easily.)

The result is a smoother, largely tear-out free surface. This works all the better the closer the cap iron is positioned at the cutting edge of the cutting iron, because this causes a stronger bending of the fibers, and the narrower the mouth of the plane is, because the cut is done immediately after lifting the chip and a follow-up of the fibers is prevented.

The cap iron must also have a narrow "breaking edge" in order to bend the chip abruptly. The term "chip breaker" is therefore unfortunately somewhat misleading, since the chip is actually only heavily bended, but not really broken.

The above illustration is from a textbook for carpenters from 1950. Personally, I think the recommended angle of 90 degrees for the breaking edge is too extreme. In my experience, this configuration leads to clogging of the plane.

A very good description of the mode of action of the double iron in contrast to the single iron (with very clear drawings) is given to us by Charles Holtzapffel in the second part of his book "Turning and Mechanical Manipulation" (published in three parts between 1846 and 1850). Above all, the connection between narrow mouth, bending of the fibers and time of actual cut is shown very clearly.

The double iron was most likely developed in England (perhaps also in France) in the first half of the 18th century. Unfortunately, it is not known from whom and when exactly. The well-known German authors of the 18th century (Halle, Sprengel, Krünitz) do not yet mention the double iron. The oldest surviving double-iron bench plane was found in 1978 in London (Cutler Street) and dated to about 1750-1780. The cutting iron and cap iron were not yet connected with a screw, but were only fixed with the wedge in the plane body. This early form of the double iron was also known in France and was even maintained into the 20th century, in addition to the later versions with short or long screw. Here is an example of this from my own collection, a smoothing plane from Peugeot Freres:

The oldest written mention of a double iron, which I know, comes from the Pennsylvania Chronicle of March 29, 1767. The plane manufacturer and tool dealer Samuel Carruthers mentions in his advertisement "double iron'd planes of a late construction". Since he mainly imported tools from England to the American colonies and only manufactured the wooden components of the planes himself, one can almost certainly assume that they were English planes (see also this article on "English Tools in America" by Charles F. Hummels).

Very soon both irons were firmly connected with a screw, which greatly simplified the fine adjustment of the cap iron in particular and the adjustment of the iron in the plane overall. Two different methods developed (probably simultaneously):

In England, a thread was soldered vertically to the top of the cap iron, both parts could thus be firmly connected with a short screw, the plane iron itself got a centered elongated slot, whereby the cap could be manually moved with a slightly loosened screw.

In France, on the other hand, two threaded pieces with a little distance to each other and horizontally to the plane iron were soldered at the bottom of the cap iron, through which a long screw ran. With this screw, the cap iron could be adjusted very precisely and held in this position. However, the cap and the cutting iron were not firmly connected in this construction, they were only pressed together by the wedge of the plane.

In the Austrian monarchy and in southern Germany, the double iron with long screw was used, while the double iron with short screw was widespread in England, America and northern Europe. In the end, the version with a short screw has generally prevailed. Georg Altmütter described 1825 as one of the first both versions, preferring the iron with a long screw, because the cap iron was much easier to adjust precisely. Weiss & Sohn (and all other manufacturers in the monarchy) supplied double irons with a long screw as standard, if a double iron with short screw was desired, this had to be specified when ordering.

Model development based on iron widths

The double plane was produced by Weiss & Sohn in 3 variants: as an ordinary double plane, with lignum-vitae sole and with iron sole. The ordinary double plane had the number 3, in the mid-1950s, as with the other bench planes, the additions "S" (for protective polish) and "H" (for hand protectors) were added to the number. Those additions appeared for the first time in catalogue No. 33 of about 1930, but only on order, only in the mid-1950s the planes were delivered by default with hand protector and and protective polish.)

The variant with lignum-vitae sole still had the number 224 in the Atlas, at the beginning of the 20th century it received the number 3D (or "d"), in 1930 the "d" was replaced by the addition "P" (for the german word “Pockholz”). The version with iron sole bore the number 216 in the atlas, from about 1900 the number 3E. In the 1920s, this model disappeared from the catalogues, strangely with one exception in a 1960 price list.

The smoothing plane, slightly shorter than the classic double plane, only appeared in the catalogues in the 1890s as a separate model, as already mentioned above. It was given the number 3A ("a") and also later the additions "S" and "H".

The model 3f, a double plane with rebates on both sides of the sole and thus actually a rebate plane, appears for the first time in a Weiss & Sohn catalogue around 1935. However, in my own collection I have a model of this plane, which certainly dates back to the 19th century. Either the model was produced but not included in the catalogs, or only made to order, or this modification was carried out by the owner. I do not yet have an answer to this question. In any case, this model remained in production until the end of the company.

The hard plane was number 215 in the Atlas, but at that time it had only a single iron and also an iron sole. From the 1890s it was given the number 3 1/2, so it was attributed to the double planes. In the catalogue of 1909 it is also depicted with a double iron. Apparently it remained in production until about 1930. Earlier I mentioned that the hard plane was replaced by the double or smoothing plane. The long production period seems to contradict this. However, I have not yet found an example of this plane, which rather suggests that it has been offered for a long time, but has hardly been used. (If someone has an example of a hard plane in their collection, I would be very grateful for photos!)

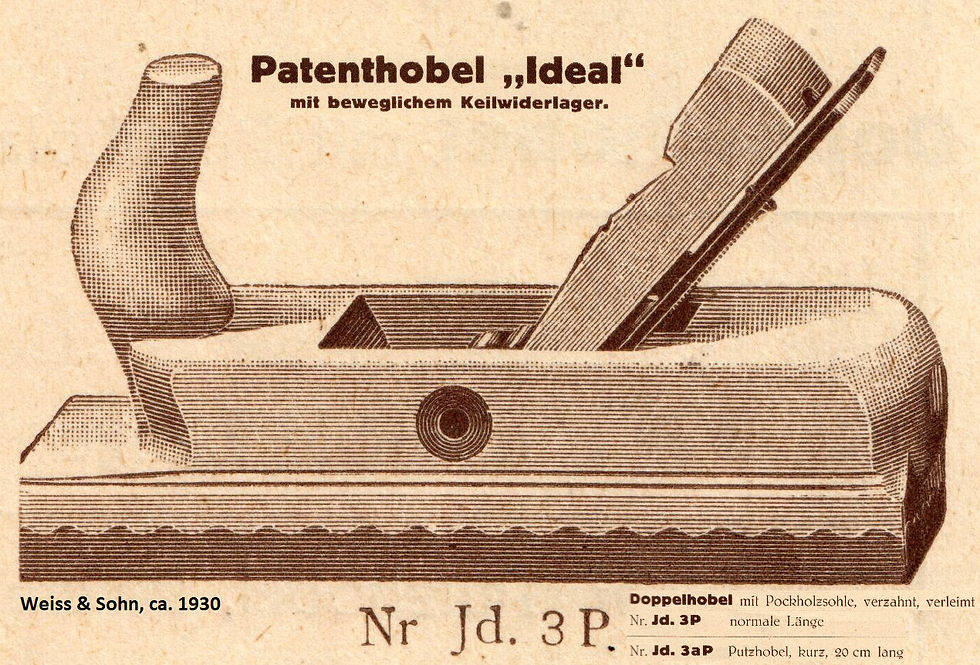

Patented plane "Ideal"

The patent for this plane, in fact for the wedge stop, was granted in 1928. In the course of this patent grant, there were some disagreements with the company Georg Ott ("Ulmia") in Germany, which had previously also patented a very similar abutment. (A large part of the correspondence at that time, consisting of objections and replies, is in my collection of documents, and I will publish it here in due course.)

The numbering of the models was analogous to the conventional bench planes, but the plane number was preceded by the abbreviation "Id" (for Ideal). In this series there were the numbers Id3 (double plane) and Id3P (double planer with lignum-vitae sole) as well as an ordinary smoothing plane (Id3a) and a smoothing plane with lignum-vitae sole (Id3aP). The additions "S" and "H" were also used from the mid-1950s onwards, similar to the usual bench planes.

Quellen:

Turning and Mechanical Manipulation, Volume II, Charles Holtzapffel, published by Holtzapffel & Co., London, 1846-1850

Beschreibung der Werkzeug-Sammlung des k.k. polytechnischen Institutes, Georg Altmütter, Wien 1825, Im Verlage bey J. B. Wallishausser

Fachkunde für Tischler Teil 1, Hans Pätzold und Kurt Willer, B. G. Teubner, Leipzig, 7. Auflage 1954